Ports are the backbone of the logistics industry, around 90% of the world’s goods are transported via it. Currently there are around 2000 ports in total across the world, combining both the smaller and large ones. Ports continue to face increased traffic, as the demands across the world sores. Working on deadlines, weather changes and keeping the track of containers efficiently is an overwhelming task.

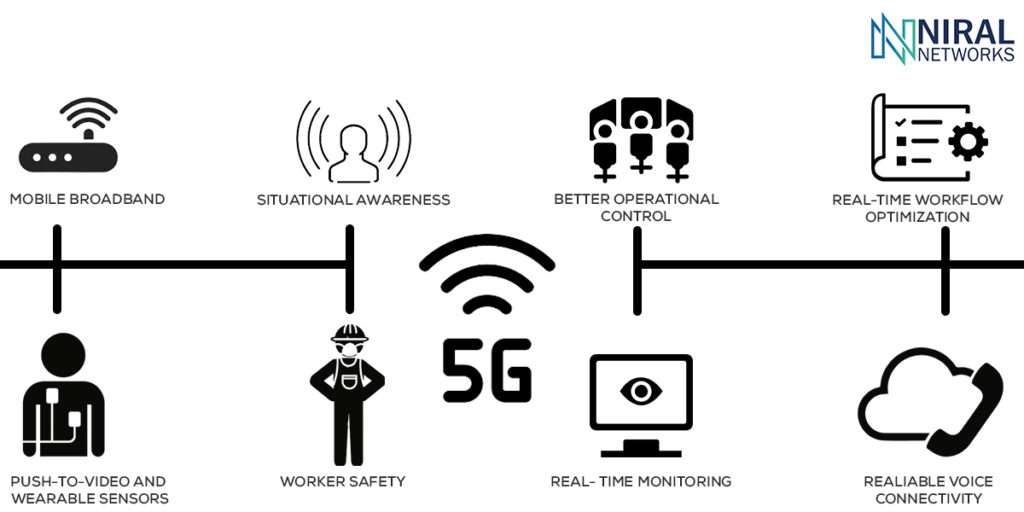

Ports need automation to meet their deadlines, track shipments with ease and manage the increasing congestion across their yards efficiently. Automation and IoT require 5G networks to perform without any hassle to perform with perfection.

Ports today still work around the traditional ways established, heavy labor input, harsh working conditions and inefficient methods of tracking containers have become a huge pain point for the port authorities. Digitization can solve these issues and create instant impact on the industry.

Read Also: Revolutionizing Ports Automation with Private 5G Networks

Ports use various kinds of cranes, each performing dedicated work. Slight delay or malfunctioning of the crane is costly, as the containers are rented on a daily basis. Poor efficiency during loading and unloading of containers result in an overall delay to the transportation timeline, while simultaneously being heavy on the pockets of ports.

Quayside container cranes and gantry cranes are two common cranes widely used in ports. The quay area is the most important service unit across the ports. Quayside container cranes are responsible for the loading and unloading of containers, hence their height is 60-70 meters. Working at such heights requires wireless communication, for remote control and monitoring.

In a typical remote control situation, a quayside container has more than 20 cameras and is densely deployed across the coastline. Higher bandwidths are must for real-time monitoring, the vertical and horizontal movement of these cranes require low latency for remote functioning.

A port contains around 60 gantry cranes function within one square km area, they too need to upload HD quality surveillance videos via 8-15 cameras. Hence a high bandwidth is required with low latency to support the quality of video.

Global trade is on the rise, and the number of mega ships keep adding up while the infrastructure of ports still remain old, challenges in finances and port congestion keep arising. This gradually becomes a big challenge for port management, as time is very crucial to keep the supply chain across the world intact. A 5G infrastructure gives a port multiple features, not only it makes the port smarter, but also economical and sustainable.

Predictive analysis helps in the correct estimation of loading and unloading, which also results in reducing congestion of traffic both across land and water. Technologies like big data and AI help in keeping the correct record of container’s location, simultaneously guiding the unmanned vehicles (cranes) to their location.

Automation is paving its way, auto guided vehicles, drones and remote controlled cranes will become common in ports. Auto guided vehicles and drones with scanners installed in them will lead to easy tracking of containers, reducing congestion and traffic across the ports.

In a typical scenario, each crane requires a person for its operation. Multiple cranes can be operated by a single operator via remote control while sitting in a controller room. The cameras need to upload videos continuously for surveillance, a private 5G network installed helps in achieving low latency, massive device connectivity and high bandwidth.

Infrastructure of ports is complicated, and deployment of optical fibers isn’t possible across certain areas. 5G is wireless, which serves as the best alternative to the current connectivity system. AI, IoT and Edge computing’s true potential is tapped by deploying 5G, which allows better synchronization, automation, along with making the ports efficient and intelligent.

The impact of 5G is clear, as the data suggests ports with 5G network installed have seen around 30% reduction in operation time and up to 15% reduction in CO2 emissions. Every industry around the world is focused on collecting data to process and implement automation, ports being the core part of the supply chain industry is an important data center, analytics of data results in betterment of asset management, faster transportation, customer experience and cost reduction. 5G private networks will enable that data generation and gathering. This will offer ports the visibility and predictability that can help them take operations to the next level.

Niral Network has Niral Controller and Niral 5G Core which can be easily installed and customized to provide an enterprise end to end solution. Niral’s team possesses the required talent and manpower to assist in companies’ needs. We are happy to help, connect and collaborate.